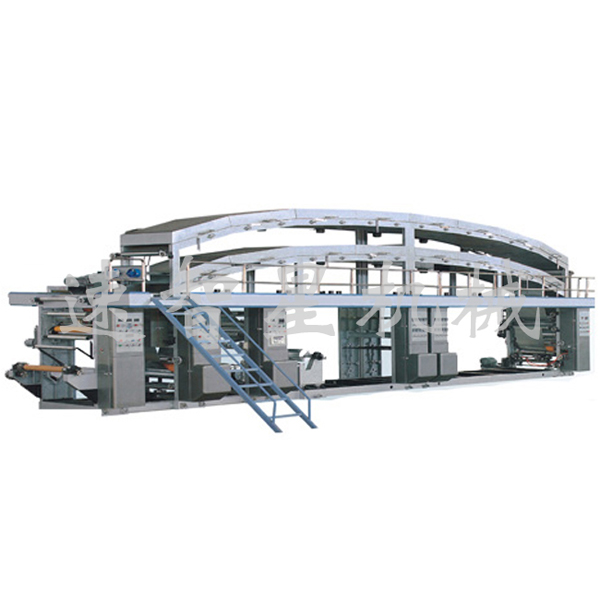

The Main Purpose

The machine imported advanced coating technology with its own production coating machines for many years experience, and this machine uses double-sided textured coating capabilities, suitable for film embroidered double-sided color, double-sided coating, electrostatic conductive film products such as film coated on both sides.

The Main Technical Parameter

| Model No. | STB-1600 |

| Coating Method | Anilox Coating |

| Coating Width | 1600mm |

| Unwind diameter | φ800mm |

|

Max-rewind diameter |

φ800mm |

|

Max-unwind diameter |

Electric Turning Double Station, Electric Lifting Single Station |

| Drying Oven Length |

Double-decked drying oven: Upper formation 18 meters; Lower level 12 meters |

| Drying Oven Tempreture | 10-200℃ |

| Coating Speed | 10-100m/min(Depending on the material) |

| Manchine Speed | 120m/min |

| Size | 19500×2600×5100mm |

| Weight | About 18T |

| Heating Method | Electric/Hot Gas/Steam |

| Working Power | While Heating 130KW;While Working 90KW |

| Power | About 32KW |

Peformancea And Features

1. The whole Machine With 6-speed motor control, tension (in volume, coated, traction and rewinding) with Japanese MITSUBISHI PLC controlled automatically by the human machine interface and touch screen control display and increase the reliability of the tension of the whole machine.

2. A form of shelving electric duplex bits, magnetic powder automatic tension control.

3. Double-sided textured coated manner, coated with heavy-Scraper Axis Dual Axis Type mechanical independent roving, Scraper Control to Manual with pneumatic, free adjustment angle, coated depends on the amount of net roll of wire, different application to change between the different pattern of the roller.

4. Double oven: Upper Layer 5 of 18 m sub-independent temperature control; the lower 12 m sub-paragraph 4 independent temperature control, heating, heated hot air in-system, enter the adjustable recirculating exhaust, drug, exhaust powerfull, dry thoroughly.

5. Inside the pulley with active synchronization with the host, the drive with the drive pulley, relief materials stretched and distorted, top-of-the cylinder and wear oven film operating platform, allows the operating workers ease of work.

6. Application roller --- Hitch Steel Roll tension in the middle with a floating synchronization swing arm boards is automatically controlled by the PLC.

7. The automatic meter rate control unit

8. The adoption of corrective EPC-to-edge, in order to take the volume up.

9. The receiving of shaft with key sub-air-handling, in order to feed shaft easy operation, air-axis pick and place a safety lock.

10. The high-precision-pressure on hitch, steel rolls with cooling water cycle through cooling rollers to film more flat, more crisp, more a cooling effect.

11. The collection in the form of material electric dual-position, with the frequency of the motor, volume vector converter by the PLC control system.

Requirements

A, according to the different requirements of customers special custom machine (limited width range of 300-2000 - mm)

B, and forms are: hand carry material type and simplex hydraulic lift simplex, electric tilting double location, turn electric zipper climbing type double location, electric wheel disc double location etc for customers to choose

C, oven heating mode are: electric heating, heat conduction oil furnace heating, steam heating, etc. For customers to choose

D, coating method is respectively: anilox roll coating, double roll coating, three roll coating, five roll coating, the comma blade coating, such as air blade coating for customers to choose

E, working speed and coating material, coating thickness, drying oven, drying temperature is proportional to the length

Process Flow

Base material, roll, coating unit, drying unit, traction unit, the winding machine

Samples

Double side conducting film

PET Embroidered film

Print the current page

Print the current page Put this page in the favorites

Put this page in the favorites Hotline:18058880288

Hotline:18058880288 Mail:ffx@wzsuzx.com

Mail:ffx@wzsuzx.com